Multipix Imaging is pleased to introduce the new MV-HLVS 2.5D Line Scan Vision System Range from HIKRobot — a cutting-edge solution that brings a new dimension of performance to industrial inspection tasks.

Designed to go beyond traditional 2D inspection, this complete kit integrates high-speed fringe projection and phase demodulation to capture detailed height variation data on the surface of components. The result is a highly accurate 2.5D profile that makes it possible to detect subtle surface defects that are invisible to standard 2D line scan systems.

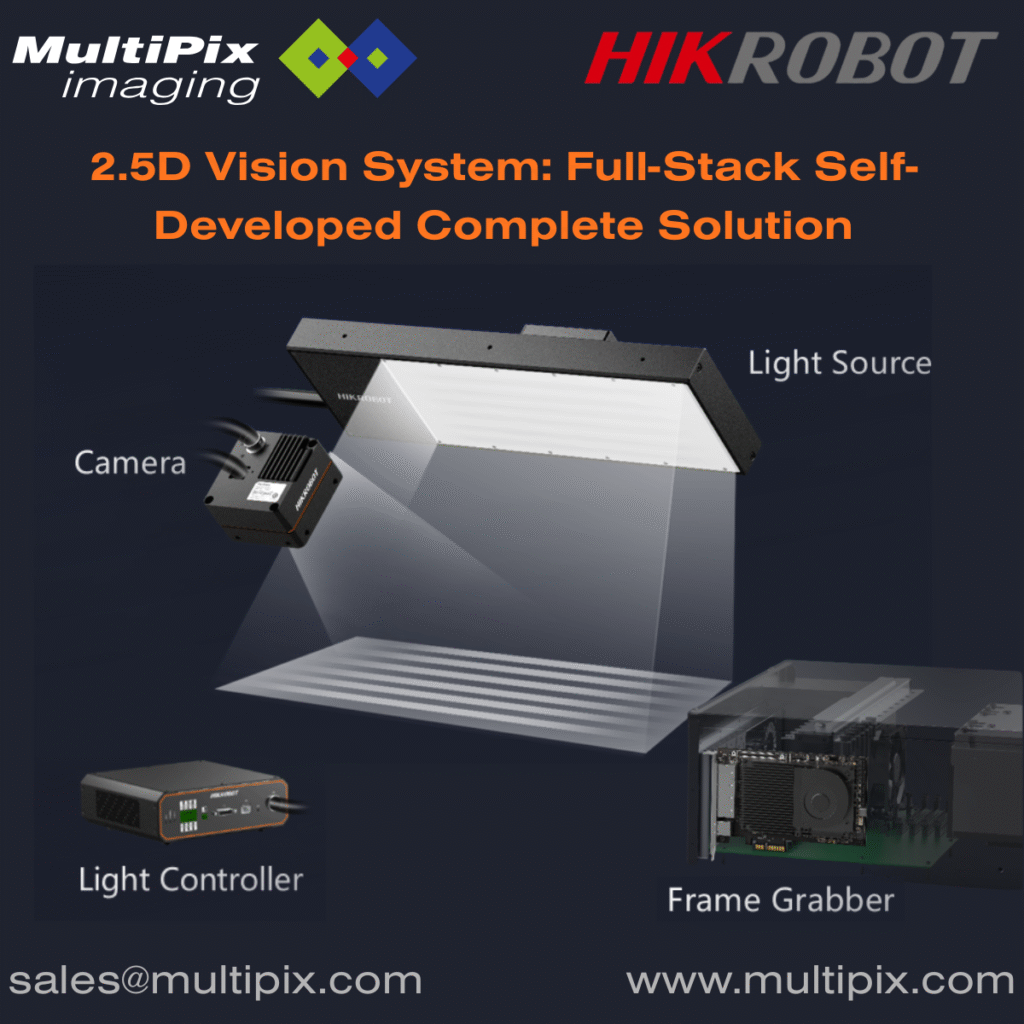

The system includes everything needed for integration: camera, light source, controller, frame grabber, laser accessories, and cables — simply add a lens and software license to get started.

Key Features

✅ High-speed 2.5D imaging with 16K resolution and line rates up to 120kHz

✅ Advanced fringe projection technology to acquire accurate height data in real-time

✅ Dual working modes – Transmission and Reflection – for flexibility across inspection tasks

✅ Detects defects including micro dents, fine scratches, stains, contamination, and dullness, even on reflective or transparent surfaces

✅ Integrated with Vision Master software for simplified setup and accurate defect recognition

✅ Provides multiple result maps in a single scan, enabling compound defect analysis

Applications

The HIKRobot 2.5D Vision System is ideal for use in industries where precision and consistency are critical:

- Lithium battery production

- 3C electronics manufacturing

- Automotive component inspection

- Metal surface evaluation

- Panel and film quality control

Whether inspecting highly reflective materials or seeking to uncover the most subtle surface variations, the HIKRobot 2.5D Line Scan Series offers powerful new capabilities for quality-focused manufacturers.

________________________________________

Discover more

To find out how this innovative technology can enhance your inspection processes, contact the team at Multipix Imaging for expert advice and support.